8V Series Eight-Groove Cast Iron Pulley Sheaves

As one of the cast iron pulley manufacturers, suppliers, and exporters of mechanical products, We offer cast iron pulley and many others.

Please get in touch with us for details.

Mail:[email protected]

Manufacturer supplier exporter of the cast iron pulley.

8V Series Eight-Groove Cast Iron Pulley Sheaves

Cast iron pulley is a pulley made of cast iron, a strong and durable material commonly used in industrial applications. Cast iron pulleys are used to transmit power and motion between the shafts of rotation by running a belt or rope around the circumference of the pulley.

The 8V series sixteen grooves tapered bushing shaft is manufactured for 8V and 8V ribbon V-belts. They range in diameter from 12.5 inches to 64.0 inches. Depending on axle size, they are made using U2 or W2 split cone bushings, which we also stock. Most of our dozens of six-groove 8V split cone shafts are manufactured from high-strength Grade 35 cast iron, phosphate-coated, and anticorrosive paint, all balanced at the factory to ensure smooth mechanical operation.

Cast Iron Pulley Parameter:

| Sheave Size | Bushing | Pitch Diameter (P.D.) | Outside Diameter (O.D.) | Type | (O.L.) | (L) | (P) | (C) | (H) | (F) | (G) | (X) | (E) | Weight (LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8S8V125 | S2 | 12.3 | 12.5 | 15 | 9-3/8″ | 6-3/4″ | 1-7/8″ | 3/4″ | 6-3/8″ | 9-3/8″ | 1-1/16″ | 5-11/16″ | 3/8″ | 140.0 |

| 8S8V132 | S2 | 13.0 | 13.2 | 15 | 9-3/8″ | 6-3/4″ | 1-7/8″ | 3/4″ | 6-3/8″ | 9-3/8″ | 1-1/16″ | 5-11/16″ | 3/8″ | 176.0 |

| 8S8V140 | S2 | 13.8 | 14.0 | 15 | 9-3/8″ | 6-3/4″ | 1-7/8″ | 3/4″ | 6-3/8″ | 9-3/8″ | 1-1/16″ | 5-11/16″ | 3/8″ | 205.0 |

| 8S8V150 | S2 | 14.8 | 15.0 | 15 | 9-3/8″ | 6-3/4″ | 1-7/8″ | 3/4″ | 6-3/8″ | 9-3/8″ | 1-1/16″ | 5-11/16″ | 3/8″ | 186.0 |

| 8S8V160 | S2 | 15.8 | 16.0 | 15 | 9-3/8″ | 6-3/4″ | 1-7/8″ | 3/4″ | 6-3/8″ | 9-3/8″ | 1-1/16″ | 5-11/16″ | 3/8″ | 210.0 |

| 8S8V170 | U1 | 16.8 | 17.0 | 15 | 9-3/8″ | 7-1/8″ | 1-1/4″ | 1″ | 8-3/8″ | 9-3/8″ | 1-1/2″ | 5-5/8″ | 15/32″ | 248.0 |

| 8S8V180 | U1 | 17.8 | 18.0 | 15 | 9-3/8″ | 7-1/8″ | 1-1/4″ | 1″ | 8-3/8″ | 9-3/8″ | 1-1/2″ | 5-5/8″ | 15/32″ | 249.0 |

| 8S8V190 | U1 | 18.8 | 19.0 | 15 | 9-3/8″ | 7-1/8″ | 1-1/4″ | 1″ | 8-3/8″ | 9-3/8″ | 1-1/2″ | 5-5/8″ | 15/32″ | 235.0 |

| 8S8V200 | U1 | 19.8 | 20.0 | 15 | 9-3/8″ | 7-1/8″ | 1-1/4″ | 1″ | 8-3/8″ | 9-3/8″ | 1-1/2″ | 5-5/8″ | 15/32″ | 251.0 |

| 8S8V212 | U1 | 21.0 | 21.2 | 15 | 9-3/8″ | 7-1/8″ | 1-1/4″ | 1″ | 8-3/8″ | 9-3/8″ | 1-1/2″ | 5-5/8″ | 15/32″ | 268.0 |

| 8S8V224 | U1 | 22.2 | 22.4 | 15 | 9-15/32″ | 7-1/8″ | 3/8″ | 1-7/8″ | 8-3/8″ | 9-3/8″ | 1-1/2″ | 5-5/8″ | 15/32″ | 253.0 |

| 8S8V300 | U1 | 29.8 | 30.0 | 15 | 9-15/32″ | 7-1/8″ | 3/8″ | 1-7/8″ | 8-3/8″ | 9-3/8″ | 1-1/2″ | 5-5/8″ | 15/32″ | 358.0 |

| 8S8V400 | W1 | 39.8 | 40.0 | 13 | 10-5/16″ | 8-1/4″ | 3/8″ | 1-1/2″ | 12-1/2″ | 9-3/8″ | 1-7/8″ | 6-3/8″ | 9/16″ | 567.0 |

| 8S8V480 | W1 | 47.8 | 48.0 | 13 | 10-5/16″ | 8-1/4″ | 3/8″ | 1-1/2″ | 12-1/2″ | 9-3/8″ | 1-7/8″ | 6-3/8″ | 9/16″ | 715.0 |

| 8S8V530 | W1 | 52.8 | 53.0 | 13 | 10-5/16″ | 8-1/4″ | 3/8″ | 1-1/2″ | 12-1/2″ | 9-3/8″ | 1-7/8″ | 6-3/8″ | 9/16″ | 762.0 |

| 8S8V580 | W1 | 57.8 | 58.0 | 13 | 10-5/16″ | 8-1/4″ | 3/8″ | 1-1/2″ | 12-1/2″ | 9-3/8″ | 1-7/8″ | 6-3/8″ | 9/16″ | 914.0 |

| 8S8V640 | W1 | 63.8 | 64.0 | 13 | 10-5/16″ | 8-1/4″ | 3/8″ | 1-1/2″ | 12-1/2″ | 9-3/8″ | 1-7/8″ | 6-3/8″ | 9/16″ | 970.0 |

Cast Iron Pulley Installation Method:

1. Check the belt pulley groove to ensure that there are no scratches and sharp edges and that all sizes are in line with standards;

2. Clean surfaces of all parts, such as hub holes, cone sleeves, bolt holes, etc. Place the cone set into the pulley and align all screw holes.

3. Grease the screws (TB1008-TB3030) and screw threads (TB3525-TB5050) and screw them into the mounting holes, but do not tighten them.

4. Clean the surface of the drive shaft, push the pulley equipped with a conical sleeve to the predetermined position on the rod, and check whether the v pulley is aligned.

5. When using the keyway, the hub must be inserted first, and there must be a certain tolerance between the keyway and the hole hub.

6. Alternately, gradually and evenly tighten the bolts in each mounting hole using a hexagon wrench conforming to the DIN911 standard until the torque shown in the table below is reached.

7. After a short period of operation (0.5 to 1 hour), check the bolt tightening torque and tighten the bolts if necessary.

8. To prevent foreign body intrusion, the connecting hole of the hole should be filled with grease.

We are one of the best-cast iron pulley suppliers.We can offer wide cast iron pulley stock.We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

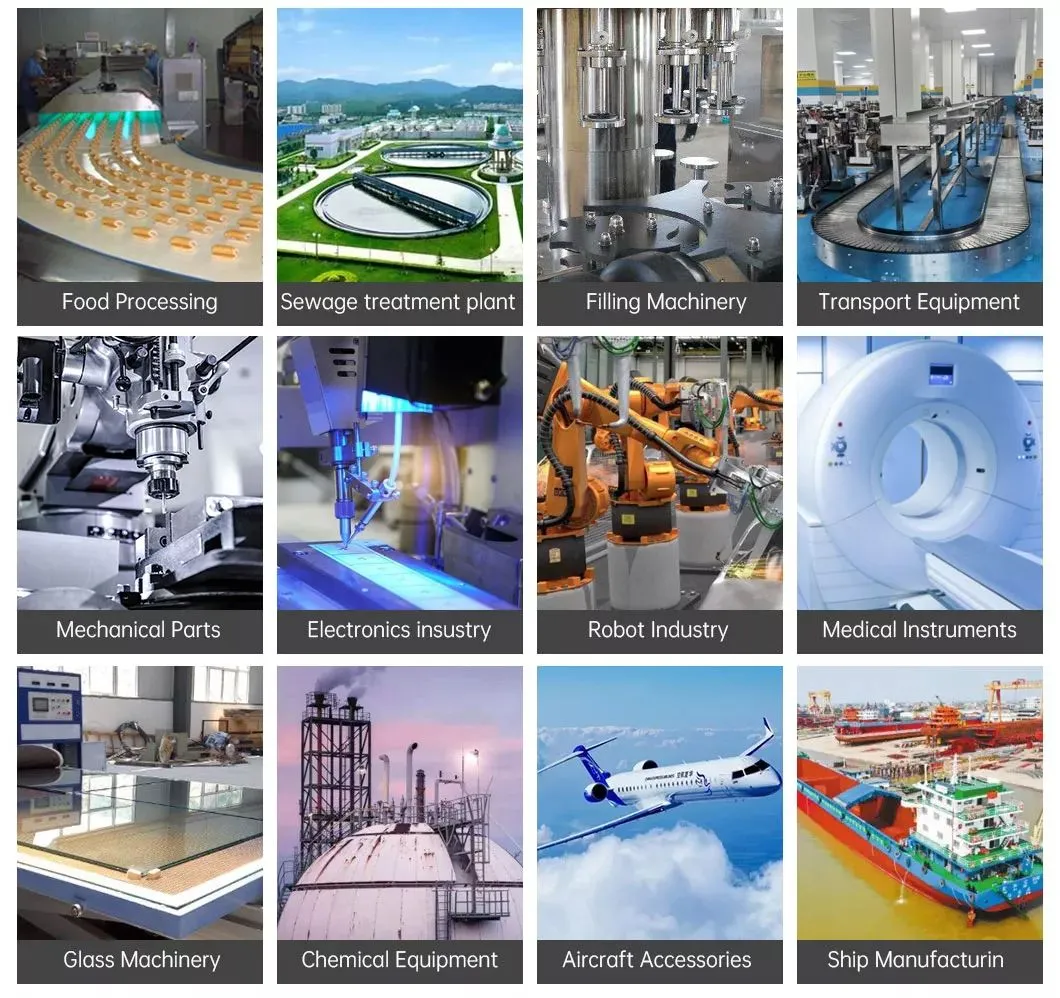

Cast Iron Pulley Application:

Industrial applications: Cast iron belts are commonly used in industrial applications such as manufacturing, mining, agriculture and construction. They are used to transmit power and motion between the rotating axes of machines and equipment.

Automotive applications: Cast iron pulley is used in automotive applications such as engines and transmissions. They are used to transfer power from the engine to the wheels and other components.

Marine applications: Cast iron pulleys are used in Marine applications such as ships and small boats. They are used to transfer power from the engine to the propeller and other components.

Aviation applications: Cast iron pulleys are used in aviation applications such as aircraft engines. They are used to transfer power from the engine to the propeller and other components.

Characteristics of Cast Iron Pulleys:

Durability: Cast iron pulleys are known for their durability. They are designed to withstand extended wear and tear periods without losing efficiency or performance.

Strength: Cast iron pulley strength can withstand high loads and stress. They are designed to transmit a lot of power and motion between axes of rotation.

Wear resistance: Cast iron pulleys are resistant to wear and tear, suitable for high-stress and high-load applications.

Heat resistance: Cast iron pulleys can withstand high temperatures without reducing or losing their strength. This makes them suitable for use in high-temperature environments.

Corrosion resistance: Cast iron pulleys are corrosion-resistant and suitable for use in harsh environments.